The Perfect Burger.

Built by Intelligence.

Fully autonomous. Data-driven. Freshly built. REET Systems GmbH combines robotics with end-to-end AI to revolutionize food logistics.

Fully autonomous. Data-driven. Freshly built. REET Systems GmbH combines robotics with end-to-end AI to revolutionize food logistics.

Precision Engineering. 24/7 Reliability.

FABAL's thermal management system maintains optimal temperature from assembly to delivery, ensuring every burger is perfectly hot and fresh.

Our advanced modular condiment-feeders deliver unprecedented variety: 13 different condiments, 15 different sauces, 9 different patties, 5 different buns, and fresh cut slices of cheese. All built and packaged in 3 types of boxes for perfect presentation.

Complete operational oversight with remote monitoring capabilities. The easily accessible cabinet at the bottom of the machine provides convenient access for maintenance and restocking, ensuring minimal downtime and maximum efficiency.

Our industrial-component based machine is built to last and consists of hot-pluggable components which allow fast exchange of components while having industrial-standard lifetimes.

We comply to all needed hygienic standards and third parties confirmed our cleaning processes and never found any alarming residues.

Predicts demand with hyper-accuracy. Optimizes supply chain logistics in real-time.

Computer vision quality control. Every patty, every bun, analyzed for perfection.

Predictive maintenance. Self-diagnosing hardware to prevent downtime before it happens.

Operational assistant. Manages workflow and staff allocation for peak efficiency.

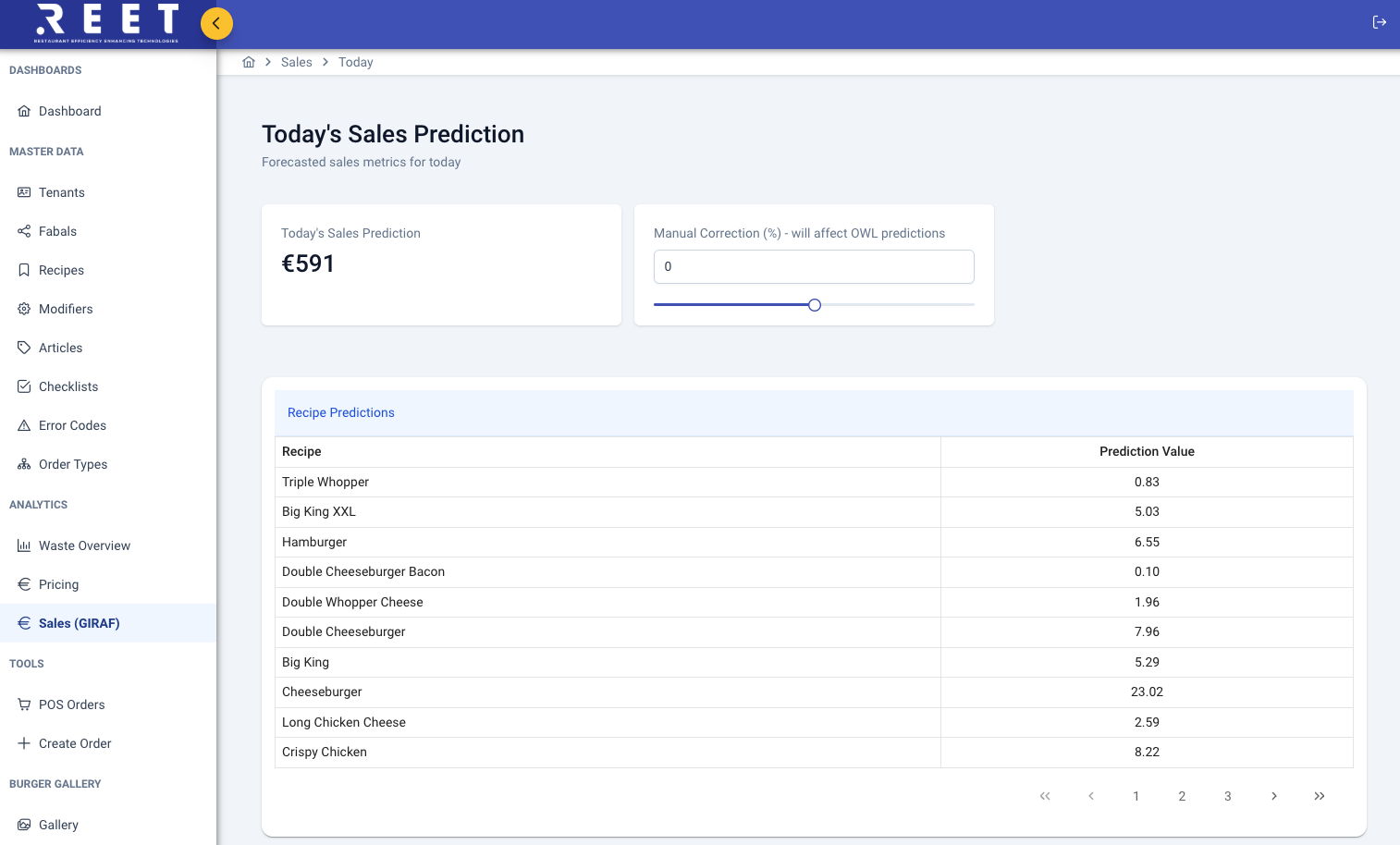

The remote management software. Controls every recipe and reports every order to your central dashboard in real-time. Complete oversight, zero friction.

Utilizes historical sales data and machine learning to forecast demand patterns up to 30 days in advance.

Automatically adjusts stock levels based on predicted demand to minimize waste and prevent shortages.

Provides live dashboards with instant insights into supply chain performance and bottlenecks.

Advanced AI algorithms continuously learn from operational data to improve accuracy over time.

High-resolution cameras and neural networks analyze every ingredient for size, color, and freshness consistency.

Automated quality checks ensure every burger meets exact specifications before packaging.

Identifies imperfections, contamination, or assembly errors with 99.9% accuracy in milliseconds.

Continuous monitoring throughout the entire production process without slowing operations.

Predicts component failures up to 7 days before they occur, scheduling maintenance during off-peak hours.

Continuous self-testing of all systems with automatic alerts for performance degradation or anomalies.

Intelligent scheduling ensures 99.5% operational availability by preventing unexpected downtime.

Network of sensors monitors temperature, vibration, pressure, and performance across all components.

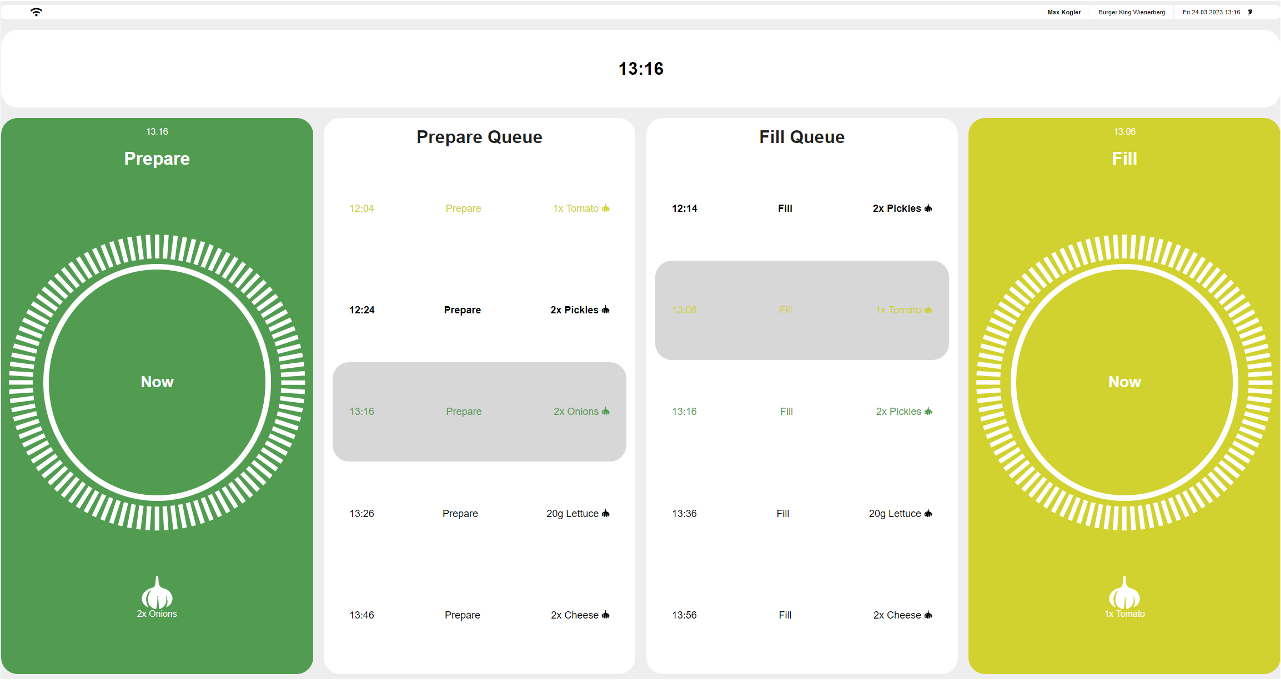

Automatically sequences production tasks and coordinates robot movements for maximum throughput.

Analyzes peak hours and staffing needs to recommend optimal workforce allocation in real-time.

Intelligent task prioritization ensures urgent orders and maintenance are handled efficiently.

Learns from operational patterns to continuously improve efficiency and reduce production time.

Unified interface providing complete visibility into all machines, orders, and performance metrics.

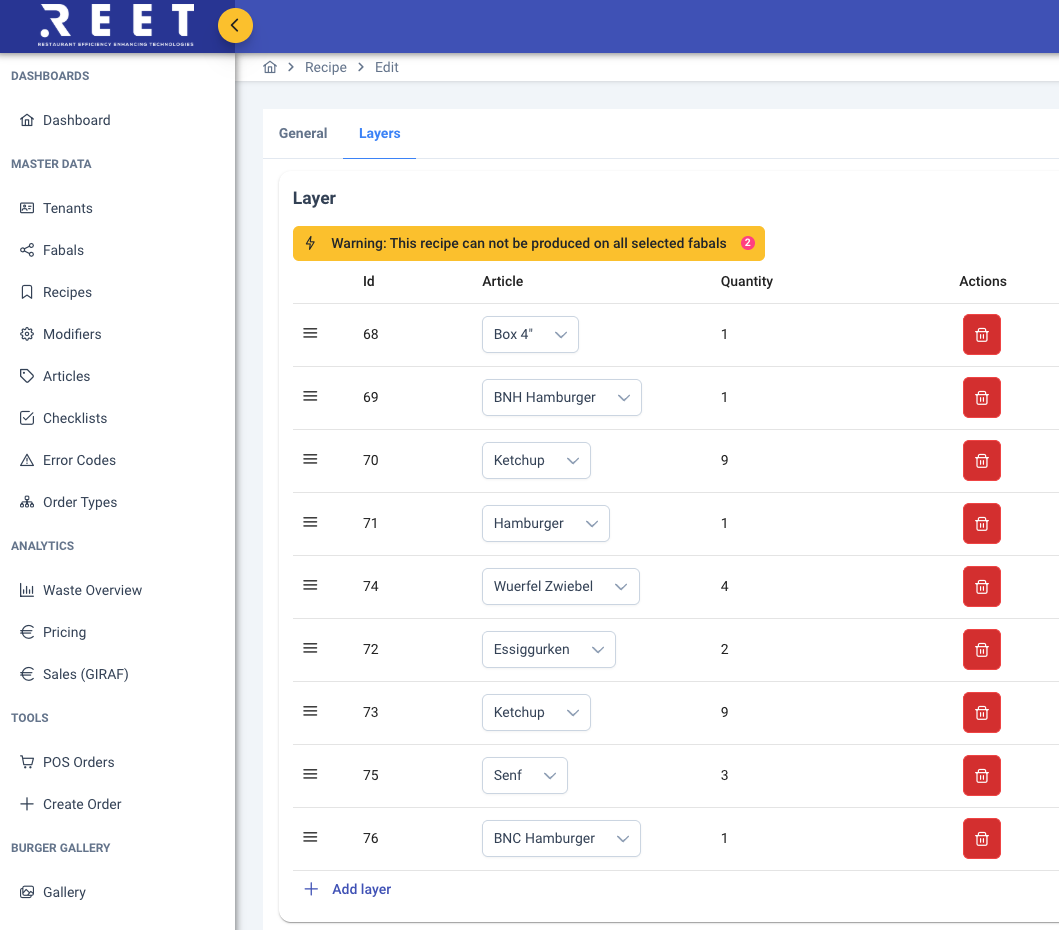

Create, modify, and deploy recipes to any machine instantly with version control and rollback capabilities.

Track every order from creation to completion with real-time status updates and delivery confirmation.

Full remote operation capabilities allowing you to manage all machines from anywhere in the world.

Forget "No pickles." FABAL allows for granular control over every ingredient. Bun type, sauce ratios, cook temp, topping layering—millions of combinations, executed instantly without error.

Request Demo